Sustainable Solutions for Decarbonizing Manufacture of wiring and wiring devices: An Exploration

This article explores sustainable solutions for reducing carbon emissions in the manufacture of wiring and wiring devices, highlighting the importance of decarbonization in the manufacturing industry.

Decarbonisation is the process of reducing carbon emissions in order to mitigate the effects of climate change. The manufacture of wiring and wiring devices is one of the industries that contribute to carbon emissions. The decarbonisation of this sector is important because it can help to reduce the impact of climate change on the environment and human health. This article will discuss the sources of carbon emissions in the manufacture of wiring and wiring devices sector, ways to reduce carbon emissions, challenges facing decarbonisation, and the implications of decarbonisation for the industry.

Sources of Carbon Emissions in the Manufacture of Wiring and Wiring Devices Sector

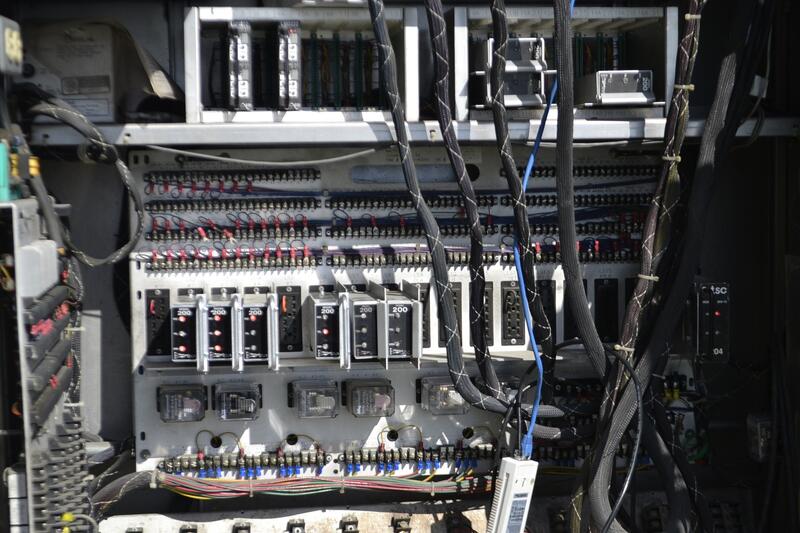

The manufacture of wiring and wiring devices involves the production of various components such as wires, cables, connectors, and switches. The production of these components requires the use of energy, which is often generated from fossil fuels. The combustion of fossil fuels releases carbon dioxide (CO2) into the atmosphere, contributing to greenhouse gas emissions. In addition, the manufacturing process itself generates carbon emissions through various activities such as transportation, packaging, and waste disposal.

Another source of carbon emissions in the manufacture of wiring and wiring devices sector is the use of materials that are carbon-intensive. For example, copper is a commonly used material in the production of wiring and wiring devices. The production of copper involves the use of energy and the release of carbon emissions. Similarly, plastics are used in the production of wiring and wiring devices, and the production of plastics also generates carbon emissions.

Reducing Carbon Emissions in the Manufacture of Wiring and Wiring Devices Sector

There are several ways to reduce carbon emissions in the manufacture of wiring and wiring devices sector. One way is to use renewable energy sources such as solar and wind power to generate electricity. This can help to reduce the reliance on fossil fuels and decrease carbon emissions. In addition, energy efficiency measures such as the use of energy-efficient equipment and processes can help to reduce energy consumption and carbon emissions.

Another way to reduce carbon emissions in the manufacture of wiring and wiring devices sector is to use materials that are less carbon-intensive. For example, using aluminum instead of copper in the production of wiring can reduce carbon emissions because the production of aluminum requires less energy and generates fewer carbon emissions. Similarly, using bioplastics instead of traditional plastics can help to reduce carbon emissions because bioplastics are made from renewable resources.

Challenges Facing Decarbonisation in the Manufacture of Wiring and Wiring Devices Sector

One of the challenges facing decarbonisation in the manufacture of wiring and wiring devices sector is the cost of implementing decarbonisation measures. For example, using renewable energy sources may require significant upfront investment, which may be difficult for some companies to afford. In addition, the use of less carbon-intensive materials may be more expensive than traditional materials, which may also be a barrier to adoption.

Another challenge facing decarbonisation in the manufacture of wiring and wiring devices sector is the lack of awareness and understanding of the importance of decarbonisation. Many companies may not be aware of the impact of their activities on the environment and may not see the value in investing in decarbonisation measures.

Implications of Decarbonisation for the Manufacture of Wiring and Wiring Devices Sector

Decarbonisation has several implications for the manufacture of wiring and wiring devices sector. One of the implications is the potential for increased competitiveness. Companies that adopt decarbonisation measures may be able to differentiate themselves from their competitors and attract customers who are environmentally conscious. In addition, companies that adopt decarbonisation measures may be able to reduce their energy costs and increase their profitability.

Another implication of decarbonisation for the manufacture of wiring and wiring devices sector is the potential for innovation. Decarbonisation requires the development of new technologies and processes, which can lead to innovation and the creation of new products and services. For example, the development of bioplastics can lead to the creation of new products that are more environmentally friendly.

Conclusion

The manufacture of wiring and wiring devices sector is one of the industries that contribute to carbon emissions. Decarbonisation of this sector is important because it can help to reduce the impact of climate change on the environment and human health. The main sources of carbon emissions in the manufacture of wiring and wiring devices sector are the use of fossil fuels, carbon-intensive materials, and the manufacturing process itself. Ways to reduce carbon emissions in this sector include the use of renewable energy sources, energy efficiency measures, and the use of less carbon-intensive materials. Challenges facing decarbonisation in this sector include the cost of implementing decarbonisation measures and the lack of awareness and understanding of the importance of decarbonisation. The implications of decarbonisation for the manufacture of wiring and wiring devices sector include increased competitiveness and innovation.