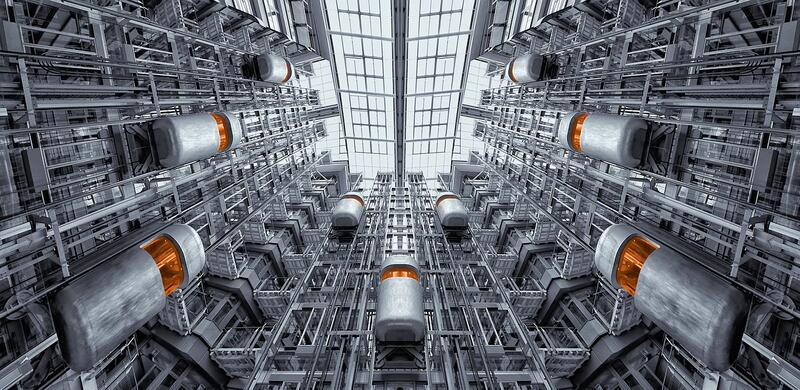

Sustainable Transitions: Decarbonizing Manufacture of lifting and handling equipment Strategies

This article discusses strategies for reducing carbon emissions in the manufacture of lifting and handling equipment, promoting sustainability in the industry.

The manufacture of lifting and handling equipment is a critical sector that supports various industries such as construction, manufacturing, and logistics. However, like other industries, it contributes to carbon emissions, which are detrimental to the environment. Decarbonisation is the process of reducing carbon emissions to mitigate climate change. In this article, we will explore what decarbonisation in the manufacture of lifting and handling equipment sector entails, why it is important, the main sources of carbon emissions, ways to reduce carbon emissions, challenges facing decarbonisation, and the implications of decarbonisation.

What is Decarbonisation in the Manufacture of Lifting and Handling Equipment Sector?

Decarbonisation in the manufacture of lifting and handling equipment sector is the process of reducing carbon emissions associated with the production and use of lifting and handling equipment. It involves the adoption of sustainable practices, technologies, and materials that reduce the carbon footprint of the sector. The objective of decarbonisation is to mitigate climate change by reducing greenhouse gas emissions, which are the primary drivers of global warming.

Why is Decarbonisation Important in the Manufacture of Lifting and Handling Equipment Sector?

Decarbonisation is important in the manufacture of lifting and handling equipment sector for several reasons. Firstly, the sector contributes to carbon emissions, which are detrimental to the environment. The manufacture of lifting and handling equipment involves the use of energy-intensive processes that emit greenhouse gases such as carbon dioxide, methane, and nitrous oxide. These gases trap heat in the atmosphere, leading to global warming, climate change, and extreme weather events such as floods, droughts, and hurricanes.

Secondly, decarbonisation is important in the manufacture of lifting and handling equipment sector because it enhances the sector's competitiveness. The adoption of sustainable practices, technologies, and materials reduces the sector's operating costs, enhances its reputation, and attracts environmentally conscious customers. Additionally, decarbonisation creates new business opportunities such as the development of green technologies and the provision of carbon offsetting services.

What are the Main Sources of Carbon Emissions in the Manufacture of Lifting and Handling Equipment Sector?

The manufacture of lifting and handling equipment sector contributes to carbon emissions through various sources, including:

- Energy consumption: The manufacture of lifting and handling equipment involves energy-intensive processes such as welding, cutting, and painting, which consume large amounts of energy. The energy is usually generated from fossil fuels such as coal, oil, and natural gas, which emit greenhouse gases.

- Transportation: The transportation of raw materials, components, and finished products contributes to carbon emissions. The use of fossil fuel-powered vehicles emits greenhouse gases such as carbon dioxide and nitrogen oxides.

- Waste management: The manufacture of lifting and handling equipment generates waste such as scrap metal, plastic, and hazardous materials, which emit greenhouse gases during disposal.

- Supply chain: The manufacture of lifting and handling equipment involves a complex supply chain that includes the extraction of raw materials, processing, and transportation. Each stage of the supply chain emits greenhouse gases, contributing to the sector's carbon footprint.

How Can We Reduce Carbon Emissions in the Manufacture of Lifting and Handling Equipment Sector?

Reducing carbon emissions in the manufacture of lifting and handling equipment sector requires the adoption of sustainable practices, technologies, and materials. Some of the ways to reduce carbon emissions include:

- Energy efficiency: The adoption of energy-efficient technologies such as LED lighting, efficient motors, and variable speed drives can reduce energy consumption and carbon emissions.

- Renewable energy: The use of renewable energy sources such as solar, wind, and hydroelectric power can reduce the sector's reliance on fossil fuels and carbon emissions.

- Material efficiency: The use of recycled materials, lightweight materials, and sustainable materials such as bamboo and hemp can reduce the sector's carbon footprint.

- Transportation efficiency: The adoption of efficient transportation methods such as electric vehicles, hybrid vehicles, and rail transport can reduce carbon emissions.

- Waste management: The adoption of sustainable waste management practices such as recycling, composting, and waste-to-energy can reduce carbon emissions.

- Supply chain management: The adoption of sustainable supply chain practices such as local sourcing, green logistics, and carbon offsetting can reduce the sector's carbon footprint.

What are the Challenges Facing Decarbonisation in the Manufacture of Lifting and Handling Equipment Sector?

Decarbonisation in the manufacture of lifting and handling equipment sector faces several challenges, including:

- High capital costs: The adoption of sustainable practices, technologies, and materials requires significant capital investment, which may be a challenge for small and medium-sized enterprises.

- Lack of awareness: Some stakeholders in the sector may not be aware of the benefits of decarbonisation or may not have access to information on sustainable practices, technologies, and materials.

- Resistance to change: Some stakeholders in the sector may be resistant to change or may not see the value of adopting sustainable practices, technologies, and materials.

- Regulatory barriers: The sector may face regulatory barriers such as lack of incentives, subsidies, or penalties for carbon emissions.

- Supply chain complexity: The sector's complex supply chain may make it challenging to implement sustainable practices, technologies, and materials across the entire value chain.

What are the Implications of Decarbonisation for the Manufacture of Lifting and Handling Equipment Sector?

Decarbonisation has several implications for the manufacture of lifting and handling equipment sector, including:

- Competitive advantage: The adoption of sustainable practices, technologies, and materials can enhance the sector's competitiveness by reducing operating costs, enhancing reputation, and attracting environmentally conscious customers.

- New business opportunities: Decarbonisation can create new business opportunities such as the development of green technologies, provision of carbon offsetting services, and the establishment of circular economy models.

- Regulatory compliance: Decarbonisation can help the sector comply with regulatory requirements such as emissions reduction targets, carbon taxes, and environmental regulations.

- Risk mitigation: Decarbonisation can mitigate the sector's exposure to climate-related risks such as supply chain disruptions, resource scarcity, and reputational damage.

Conclusion

Decarbonisation in the manufacture of lifting and handling equipment sector is critical to mitigating climate change and enhancing the sector's competitiveness. The sector contributes to carbon emissions through various sources such as energy consumption, transportation, waste management, and supply chain. To reduce carbon emissions, the sector can adopt sustainable practices, technologies, and materials such as energy efficiency, renewable energy, material efficiency, transportation efficiency, waste management, and supply chain management. However, decarbonisation faces several challenges such as high capital costs, lack of awareness, resistance to change, regulatory barriers, and supply chain complexity. The implications of decarbonisation for the sector include competitive advantage, new business opportunities, regulatory compliance, and risk mitigation.